Description

Marvel 15” x 20” Vertical Tilt Frame Automatic Saw, Model E380A PC3

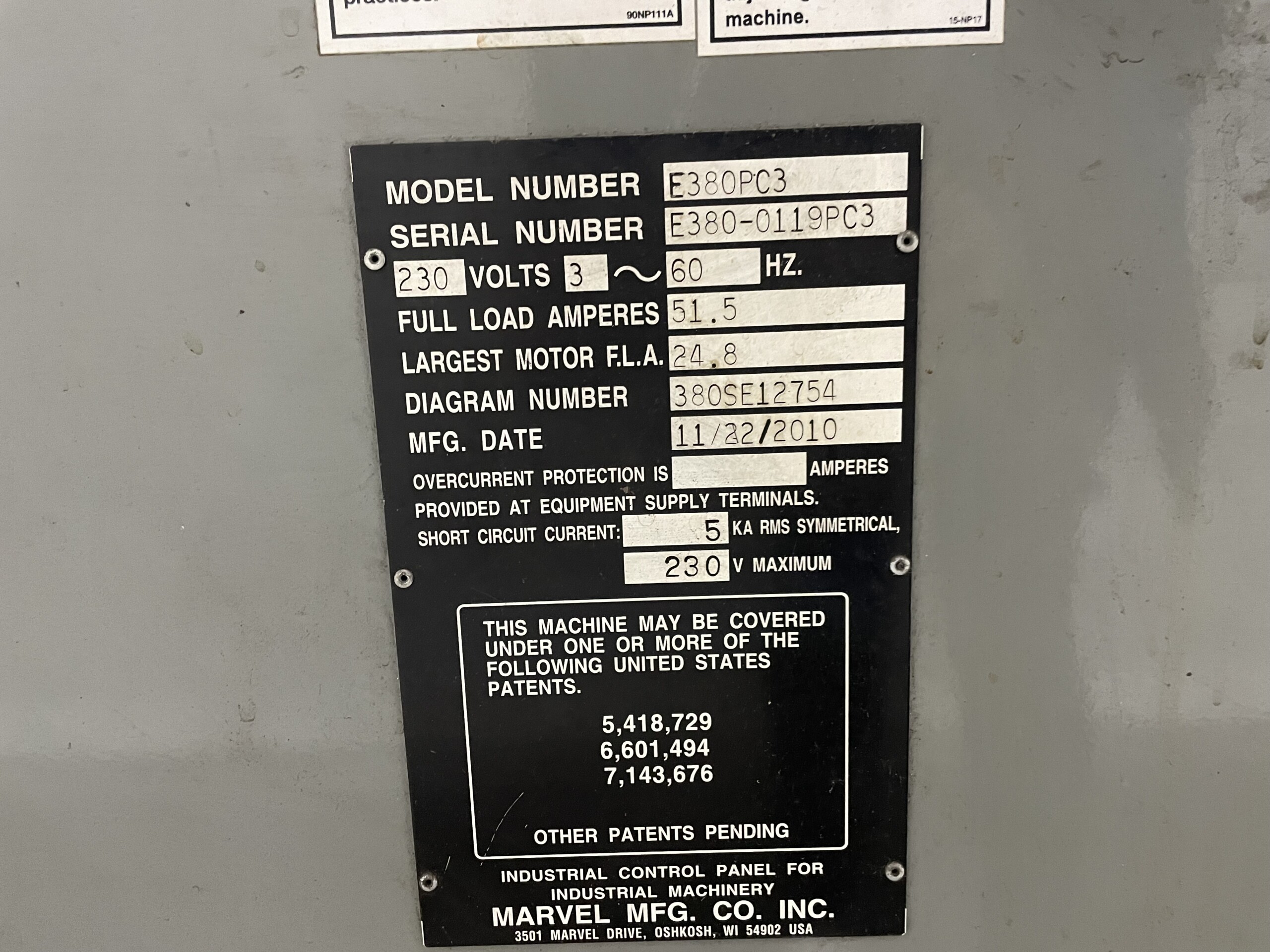

Serial # E380-0119PC3

Asset # 16266

SPECIFICATIONS & FEATURES

Capacity Rectangle Round

Nominal 3º Cant 14.5″ x 20″ (368 mm x 508 mm) 14.5″ (368 mm)

Blade at 45o 14.5″ x 13.5″ (368 mm x 343 mm) 13.5″ (343 mm)

Blade at 60o 14.5″ x 8.75″ (368 mm x 222 mm) 8.75″ (222 mm)

Blade at -45o 14.5″ x 12.75″ (368 mm x 324 mm) 12.75″ (324 mm)

Blade at -60o 14.5″ x 7.75″ (368 mm x 197 mm) 7.75″ (197 mm)

Blade Drive 5 HP electric with sensor less vector control for smooth acceleration and full torque.

Speed Range Infinitely variable: 60 to 400 FPM (18 to 122 m/min). Blade speed can be automatically set when material is selected.

Tilting Column For miter cutting up to 60o left and right of vertical. Variable speed, inverter driven, electronic tilt- Includes encoder feedback and touch screen display & control, for precision miter positioning. Electrically powered, chain driven, with encoder feedback and AMADA MACHINERY PC3 controller.

0° – 3° Canted Column Adjustable 0 or 3-degree forward approach angle, for notching, or increased efficiency in cutting of structural materials. Must specify if 0° or straight column set up is desired as the machines are by default shipped from the factory in 3° Canted Column.

Feed Force Direct Force Sensing Electric Ball Screw Feed which combines more consistent feed force with greater control, 0 – 300 lbs. (0-1335 N), column travels on re-circulating linear ball ways. Feed pressure can be automatically set when material is selected.

Jammed Blade Protection Automatically senses resistance as the column returns and stops to prevent blade damage.

Blade 16’ (4877 mm) long x 1.25″ (32 mm) wide, .042″ (1.07 mm). One Welded-Edge Band is furnished with each machine as part of standard Start-up supplies.

Blade Guide Patent pending Rotating Easy Load Combination Carbide and Ball Bearing Roller guides with self-tensioning design.

Blade Tension Hydraulically controlled, 35,000 psi. max. (241 MPa). Machine equipped with automatic blade break / blade stall shut off switch.

Upper Blade Guide Arm Hydraulically positioned and locking, travels on linear guides, controlled through PC3 touch screen control.

Vises Hydraulic, half stroking with 6.7” (170 mm) high x 11.4” (290 mm) wide 60o faceplates. Optional variable vise pressure available. (Option Code M9A).

Coolant System Built-in Flood system (Capacity of 26 gallons), available with Drop Lubrication system (requires compressed air connection) (Option Code ML2), including chip pan with chip removal ramp (optional Manual Chip Conveyor available).

Work-Rest Rollers One ball bearing roller on the entry side of the machine bed.

Flushing Hose Flushing Hose Washes away chips from hard-to-get-at places reducing clean-up time.

Automatic Bar Feed The Automatic Bar Feed design features a 48” stroke length with indexing speeds of up to 70 ft./min., and creep speeds of 33 in./min. The bar feed vise is electrically driven and combines precision double ball screws with preloaded re-circulating ball linear guides, resulting in positioning accuracy of +/- .005” per index. The vise itself is hydraulically clamped to prevent material slippage. Material can also be fed through the machine manually in both directions using the shuttle vise.

Left to Right Work

Motors Main Drive: 5 H.P. (3.75 kW), Vector Duty Induction Motor TENV

Coolant Pump: 1/8 H.P. (.1 kW), I.P. 54 Rating, totally enclosed motor built-in integrally.

Hydraulic Pump: 2 H.P. (1.5 kW), totally enclosed fan cooled, ball bearing, system pressure 800 psi

(5.5 MPa).

Controls IEC fused disconnect switch and magnetic motor starters with overload and low-voltage protection. Power supply provides low voltage (24 volts DC) control to all push buttons at operator’s control panel and machine lighting circuits. PLC control and drives mounted in moisture-tight compartment with vibration isolation mountings. Electrical Equipment conforms to National Electrical Code NFPA 79. The Electrical Control Panel is U.L. Labeled E56388.

Machine Weight 5,900 lbs.

Maximum Weight Capacity 500 lbs./foot, up to a maximum of 7,000 lbs. and 1,200 lbs. evenly distributed on the machine table. Table height is 40”.

Saw is equipped with second machine vise (F4) and automatic mist lube (ML2).

Preliminary Specifications – Subject to Verification