Do you have a Swiss army knife of machines in your shop? An ironworker is a very versatile robust machine that could save you a lot of time and valuable shop space. Do you need to punch holes on occasion? Shear less than 12” flat stock? Shear an angle? Notch a part? A single machine can replace several in your shop. Most ironworkers can punch, shear, notch and bend anything from steel plate to angle iron! In addition, there are many accessories that can increase capabilities with rod, round & square bar stock, channel iron, I-Beam and pipe. After purchasing an ironworker, our customers say they don’t know what they would do without one.

The Basics

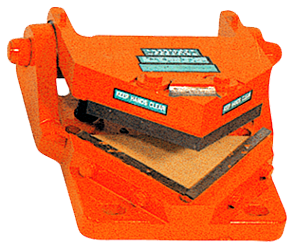

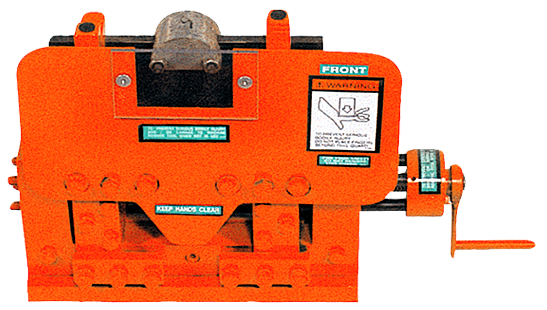

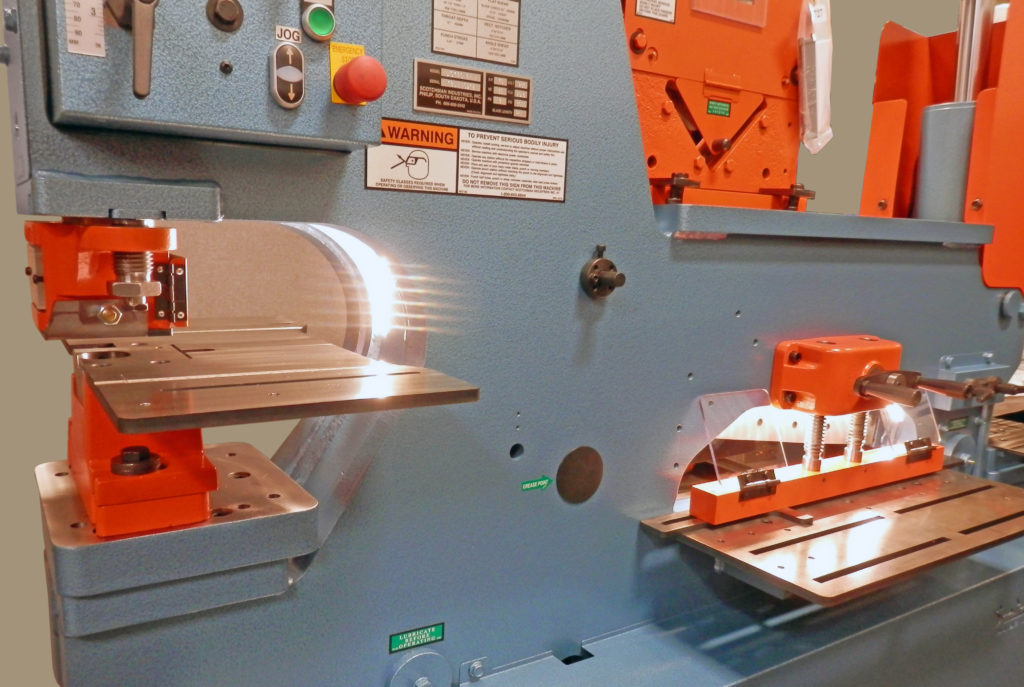

So, you want to start looking at an ironworker? Where do you start? First, most entry level ironworkers are single operator ironworkers. This means that a single motion controls both sides of the ironworker so it is only practical to have one fabricator using the ironworker. Whereas a higher production ironworker is a dual operator, so an operator can be at each end of the ironworker and the motion at each end works is independent of each other. (The ironworker pictured is a single operator)

Capacities

Next, ironworkers are rated by tonnage. This is the tonnage of the punch station, for example a 40-ton ironworker can punch a 1” hole in ½” material. While an 80-ton ironworker can punch a 1” hold in 1” material. Generally, the rest of the capabilities increase with the size of the ironworker but there is no standard that a 40-ton ironworker will by default shear a ½” x 4” piece while an 80-ton will shear 1” x 6” flat stock. So always check the capability for the processes you need in an ironworker. In addition, compare different brands and styles of ironworkers by their capabilities in the stations you need, not just the overall tonnage of each machine. Another consideration is to be aware; some ironworkers are rated in metric tons which is 2,200 lbs. instead of the U.S. ton is 2,000 lbs. Our new and used ironworkers are organized by tonnage.

Your Application

Keep in mind the type of material you are punching; most capabilities are rated at mild steel with 60,000 – 65,000 pounds of tensile strength. It is generally recommended to get a machine 20% bigger than your largest/thickest job. Though you know your application, if you only need that thickness on rare occasion then there is no need to get a larger machine. Just remember a bigger ironworker can easily do smaller jobs while a small ironworker can’t do large jobs.

Things to Consider

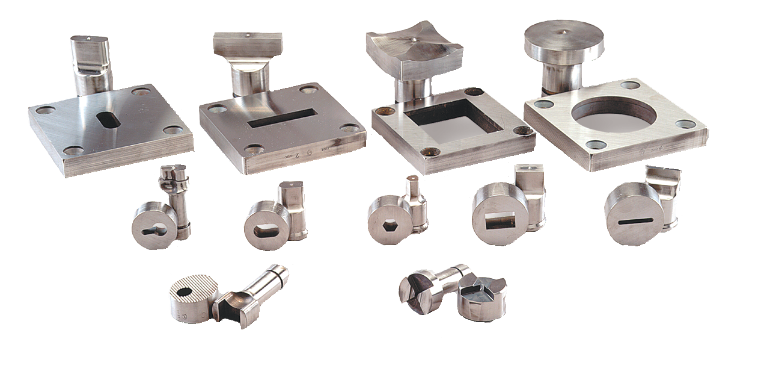

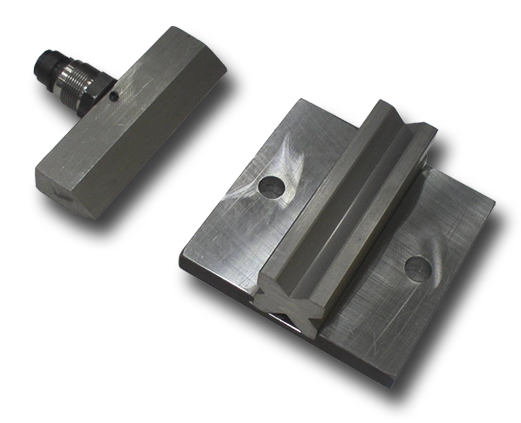

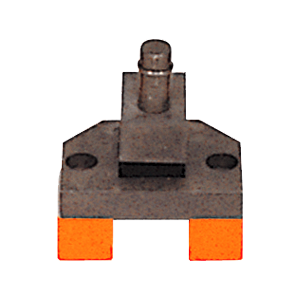

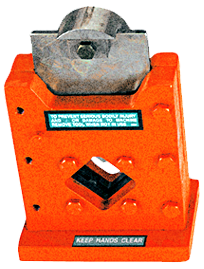

Also look for the throat size of the punching station, as most can only punch within 6”-10” of the edge of your material. Punches are not just for round holes! There are hundreds of styles, sizes, and shapes for punch tooling. Check out this catalog, you might find a type of punch that you didn’t know existed!

More Tooling

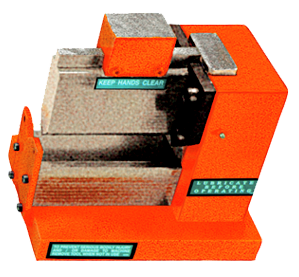

LED Backlighting for Easy Visibility

Helpful Links & Information

Vander Ziel Machinery represents several different brands of ironworkers as each has its benefits and disadvantages. We recommend the brand and type of ironworker depending on YOUR individual application. Click here to check our our new ironworkers, we represent Scotchman, Amada Marvel, and Piranha. We have thoroughly tested and tried each of these brands to ensure you get a quality product that will help get your job done!

We also have used ironworkers, click here to check those out. Vander Ziel Machinery checks out every machine and posts a video of it running.

If we can help answer any more of your questions, please give us a call or email us!